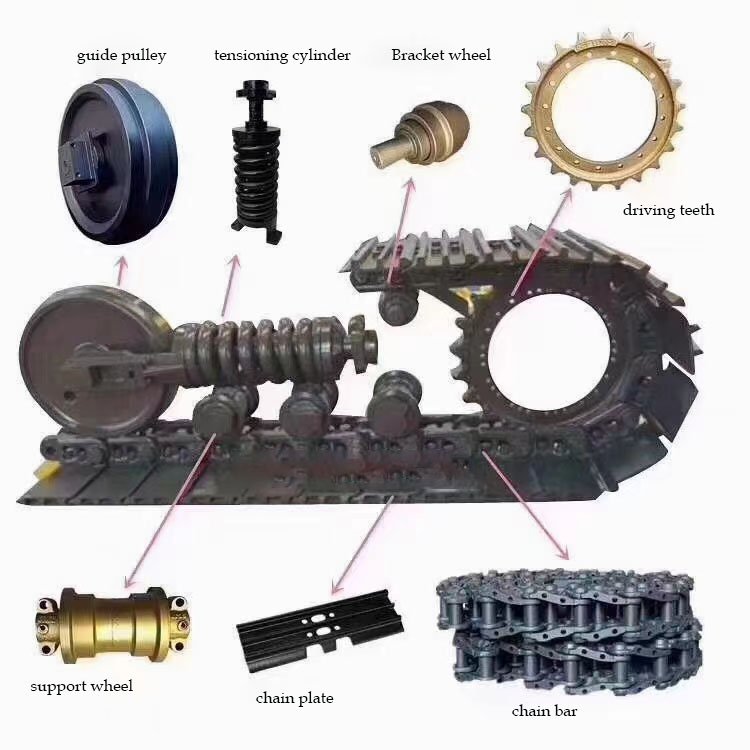

Drive Gear

Brands:cat/Komatsu/SANY

Customized drive gear is an indispensable key components in excavator travelling, slewing and other actions, and they play a vital role in mechanical transmission.

The following is a detailed introduction to the drive gear:

I. Definition and function

Excavator customized drive gear are mechanical parts with teeth that can mesh with each other, and they transmit power and torque through the meshing of gears, so that the various parts of the excavator can coordinate their movements.

In excavators, the customized drive gear is mainly used in the walking mechanism, slewing mechanism and other key parts to ensure that the excavator can work stably and efficiently.

2. the Type and characteristics

There are many types of excavator transmission gears, which can be divided into various types according to the axiality and tooth shape of the gears.

The following are some common types and their characteristics:

Parallel shaft gears:

Spur gear:

the toothed part is parallel to the central axis, classic gear type, strong load carrying capacity.

Helical gear:

tooth line is helical, smooth transmission, less shock, vibration and noise, suitable for high-speed and heavy load occasions.

Internal gear:

teeth on the inner circle, commonly used in internal gear mechanism.

Intersecting shaft gears:

Straight-toothed bevel gears:

tooth line and section cone line of the same bus, easy to manufacture, widely used in transmission systems.

Arc gear bevel gear:

tooth line for the curve, with helix angle, strong bearing capacity, low noise, but manufacturing difficulty.

Staggered shaft gear:

Worm gear:

used to transmit the movement and power between two staggered shafts, can obtain a large transmission ratio, but the transmission efficiency is relatively low.

In the excavator, the walking reducer gear is generally composed of 2-3 stages of deceleration, and the slewing reducer is generally composed of 2 stages of deceleration, and these gears are combined together to achieve the precise control of the excavator’s walking, slewing and other movements by means of different reduction ratios and transmission methods.

3. Material and process

Excavator transmission gears are generally made of high-quality high-strength alloy steel, the surface of which is carburised and hardened to improve its load-bearing capacity and wear resistance.

Manufacturing process, modern gear processing technology has been quite mature, including hobbing, milling, grinding and other processing methods, can be selected according to different gear types and precision requirements.

4. Application and maintenance

Excavator transmission gears play a vital role in excavators, they have a wide range of applications, from the walking mechanism to the slewing mechanism, are inseparable from the gear transmission.

In the process of use, it is necessary to regularly check and maintain the gears, including cleaning, lubrication, fastening and other work, in order to ensure the normal operation of the gears and extend the service life.

The customized drive gear transmits the engine power accurately and efficiently to the various working parts of the excavator through precise meshing and transmission to achieve the normal operation of the excavator.

Maintenance:

Regularly check whether the lubricating oil is sufficient to ensure that the gears do not overheat or wear out during operation.

Replace worn gears regularly to avoid loss of transmission efficiency or damage to other parts due to worn gears.

Keep the gear transmission system clean to avoid dust and dirt from entering the gear box, which will affect the operating efficiency and life of the gears.

In summary, excavator transmission gears are indispensable key components in excavators, they provide a strong guarantee for the normal work of the excavator through precise transmission and stable performance.

Overview of Company

Certificates

Factory

Service:

1.Sample service: samples are provided according to customers’ instruction.

2. Customied services: goods can be customized according to customers’demand.

3. One year warranty, some additional products will be supplied next time if they are in bad condition.

Reviews

There are no reviews yet.